Add to Cart

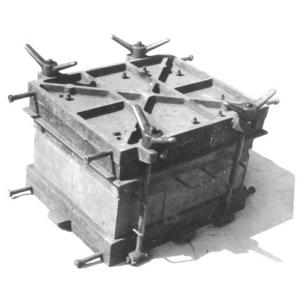

Green Sand 0.005mm Foundry Casting Molds 50,000-100000 Shots

We will be high quality, high efficiency and more professional to provide competitive One-Stop Service to our customers, and be distinctive and successful in everything we do

| Green Sand 0.005mm Foundry Casting Molds 50,000-100000 Shots

| |

|

Raw material |

Grey Iron, Ductile iron, Steel |

|

Testing equipment | Casting sand hardness tester ,Spectrum analyzer ,Carbon& sulfur analyzer ,Carbon &silicon analyzer, Tension tester, Rapid temperature measuring probe, Hardness tester, Metallographic analysis microscope; |

|

Other Equipment | Gantry Machining Center, OKUMA 4 axis &5 axis, Inductothem Electric furnace 10 Ton , Sand blasting machine, Resin boned machine, |

|

Manufacturing technique |

Sand casting, Moulding Line |

| Application | Milling machine ,vehicle mould, steam turbine, mining machine, construction machine, Wind generator… |

| Advantages | complete testing equipment and testing procedure to ensure casting elements content fulfill requirements ; Testing proceeded in cast sand, raw material, molten iron , finished product |

| Package | Wooden box |

| Needed information to quote | Material, Drawing, Heat treatment, work allowance, Need Machining or not. |

Manufacture Process

1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

Our Advantages

1. We are the well-known foundry mould manufacturer in China and we have large gantry machining centers,30 sets imported high speed machining center,more than 40 sets general machine tool equipment.Professional undertake various kinds of superior difficulty and complex casting Mould;

2. We have 36 senior mould designers, to ensure reasonable / safety / high efficiency mould design and ensure the fast mould delivery and rational mould structure, make the process more safer and the production efficiency more higher;

3. We using numerical control machine tool to manufacture the mould cavities, to ensure a even thickness ;

4. We using ZL104 Aluminium to casting the mould, to manufacture a high strength mould;

5. For the big mould, we using Ø22*1 copper tube as cooling pipe, with water spray system, to get a nice cooling effect;

6. We Have (TEF10N) coating on the mould surface, it can reduce the friction, anti water/static electricity/acid-base/high-temperature, with this we can ensure the pattern has smooth surface without distrotion, and easy to demould;

7. All the screws we using stainless steel screw, easy to disassemble during maintenance